After twenty years in the flooring business, one thing is clear: the phone calls that come in two years after the job is done almost always trace back to what went into the slab at the factory. A kitchen floor cups along the seams in winter. A retail store’s planks start telegraphing every subfloor nail. A distributor opens a container and finds half the boards a shade lighter than the sample. All of these headaches start with raw material decisions made months earlier. Stone powder grade, PVC resin quality, plasticizer type, recycled content, and batch-to-batch consistency are not just line items on a spec sheet. They decide whether an SPC floor stays flat and locked for a decade or begins to fail in eighteen months.

Stone Powder Quality: The Real Driver of Core Density and Dent Resistance

Stone powder is the heavy hitter in an SPC core—usually 65–75 % by weight. Get it wrong and nothing else in the formula can save the board.

Purity and Particle Size in the Real World

Run high-purity calcium carbonate—98.5 % or better, 1000–1500 mesh—and the powder packs tight during extrusion. The result is a core that hits 1.95–2.10 g/cm³ every time. Drop to quarry dust with 3–5 % silica or clay and density falls to 1.80 or lower. Walk across those boards with a loaded office chair and the difference shows up immediately. The softer core takes a permanent set; the dense one bounces back. On jobsites with radiant heat or big south-facing windows, low-density cores telegraph every little subfloor bump once the slab warms up. Contractors see it all the time and hate writing the call-back report.

Moisture and Impurities That Bite Later

Cheap stone powder often carries 0.3–0.5 % moisture. That water flashes to steam when the sheet hits 180 °C in the calender, leaving tiny voids that open up as micro-cracks months down the road. Iron impurities are worse. Even 50 ppm can oxidize and turn a light gray decor faintly yellow in the first summer. Seen it in coastal warehouses where the sun beats on the floor all day. The boards that stay bright are the ones made with clean, dry powder from the start.

PVC Resin Grade: What Keeps the Locks Tight and the Floor Flat

PVC is the glue that holds the stone together and gives the board its memory.

Virgin Resin versus Recycled in Everyday Jobs

Virgin PVC with a K-value of 66–68 builds long, uniform polymer chains. The locking profile cut from that resin holds 1200–1500 N pull-apart strength year after year. Mix in 30–40 % recycled post-industrial grindings and the average chain length drops. Pull strength falls below 800 N in the first couple of heating seasons and gaps open up along the long edges. Seen it in big-box retail floors that look fine at opening day and start clicking under shopping carts by Black Friday.

Heat Tolerance That Matters on Site

Higher-grade resin stays rigid up to 80 °C or more. That matters when the slab temperature hits 60 °C under dark furniture in a sunny showroom. Lower-grade resin softens closer to 55 °C and the floor starts to dome or dish over minor subfloor irregularities. Radiant-heat jobs are unforgiving. One degree too soft and the installer spends the weekend pulling up planks.

Plasticizer Standards: Flexibility That Does Not Walk Away

Plasticizers keep the board from turning brittle, but the wrong ones migrate out and leave trouble behind.

Phthalate-Free versus Old-School Chemistry

DOTP and bio-based plasticizers stay put. The floor keeps the same Shore D hardness ten years later. Old DOP formulations bleed plasticizer into the adhesive or the air, especially once the floor sees 40 °C day after day. The surface gets hard, micro-cracks form under rolling loads, and the floor sounds hollow. European projects now demand phthalate-free certification at the dock. Anything else gets turned away.

Dosage Sweet Spot

Too little plasticizer and the floor is stiff and noisy. Too much and the core gets gummy, locks soften, and indentation recovery suffers. The window is narrow—roughly 26–32 phr depending on resin grade. Factories that chase the bottom price per kilo often land outside that window and pay for it with callbacks.

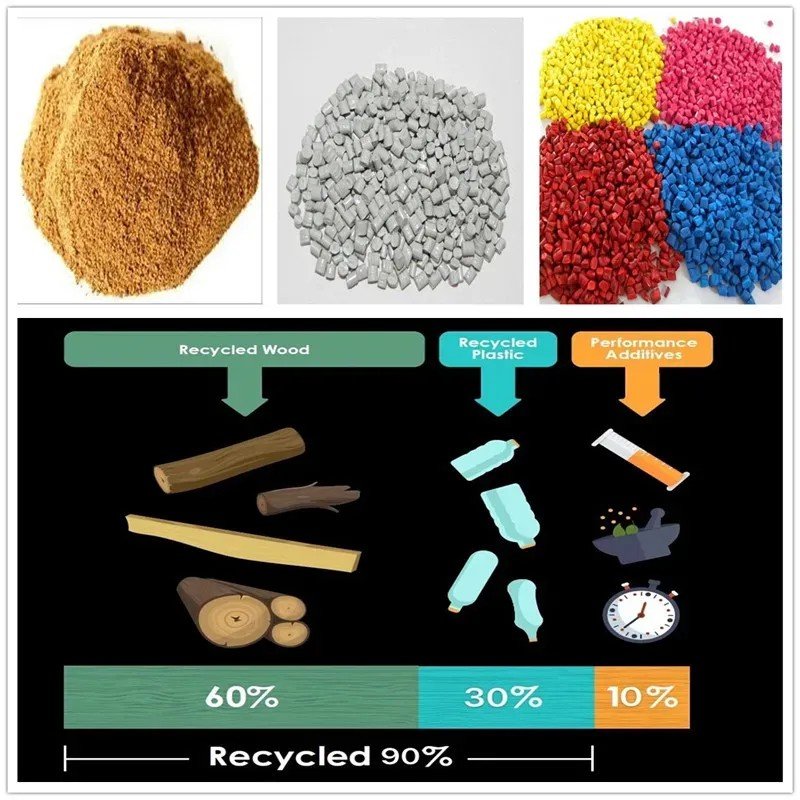

Recycled Content Ratio and Batch Consistency: The Hidden Cost Drivers

Recycled PVC sounds green on paper, but the numbers tell a different story on the floor.

How Much Recycled Material Actually Works

Up to 15–18 % recycled post-industrial PVC can stay within spec if the source is clean and consistent. Push past 25 % and density drops, expansion coefficients climb, and locking strength suffers. Seen 40 % recycled boards in a grocery store that peaked at the seams after one winter because the coefficient of expansion was almost double the virgin-material planks laid next to them.

Batch-to-Batch Reality

Even virgin-material runs can drift if the powder lot or resin lot changes mid-production. A half-shade color difference between pallets is enough to make a 5000 m² hotel lobby look patched together. Tight incoming inspection—laser particle analysis on every truck of powder, rheology checks on every resin batch—keeps variation under control. The floors that install without callbacks come from plants that treat raw material like the make-or-break factor it really is.

Introducing Shandong Lanhe Import and Export Co., Ltd.

Shandong Lanhe Import and Export Co., Ltd. has been producing SPC flooring for over fifteen years, shipping to more than sixty countries worldwide. Independent production lines and in-house research teams give the company direct control over every ingredient that goes into the core. Lanhe uses only virgin PVC resin and high-purity calcium powder, keeping recycled content to an absolute minimum and testing every incoming batch for consistency. The result is flooring that hits high density numbers run after run, stays flat through temperature swings, and locks tight for the long haul.

Conclusion

Raw material quality is not a minor detail in SPC flooring. It is the difference between a floor that quietly does its job for ten or fifteen years and one that starts giving trouble before the warranty expires. Premium stone powder builds real density and dent resistance. Virgin resin and modern plasticizers deliver lasting flexibility and heat tolerance. Controlled recycled ratios and strict batch testing prevent the variation that shows up on the jobsite. When these elements line up, the finished floor installs easily, wears evenly, and stays looking good long after the crew has moved on to the next project.

FAQs

How does stone powder quality affect SPC flooring density in real installations?

Clean, fine powder above 98.5 % purity packs tighter, routinely delivering cores over 2.0 g/cm³ that shrug off chair legs and dropped tools.

Why does virgin PVC resin matter for long-term SPC flooring stability?

Longer polymer chains keep locking strength high and expansion low, preventing gaps and peaking that appear with recycled-heavy formulas.

What happens when plasticizer standards fall short in SPC flooring performance?

Old-style phthalates migrate out, leaving the surface hard and crack-prone within a few years, especially in warm climates.

How does recycled content ratio influence SPC flooring density and durability?

Above 20–25 %, density drops noticeably and thermal movement increases, leading to seam issues in large open areas.

Why is batch consistency critical for SPC flooring raw material quality?

Even small lot-to-lot shifts show up as color drift or slight size differences that become obvious once thousands of square meters are down.