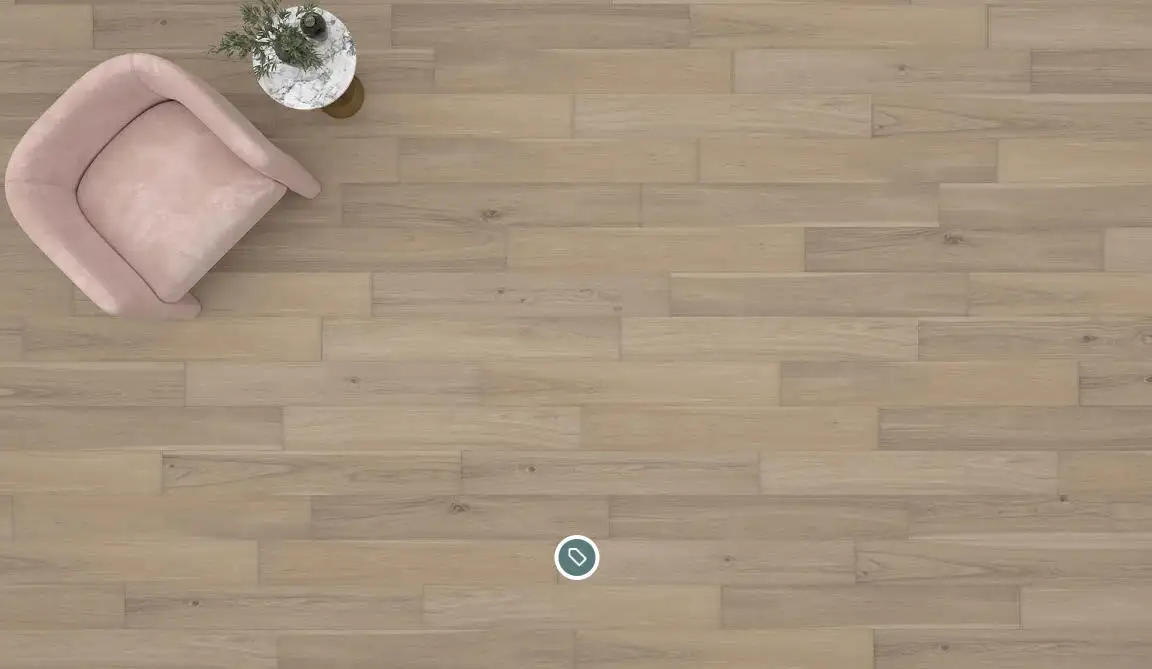

Laminate flooring is now a leading selection for residents and commercial entities wanting a sturdy, fashionable, and economical substitute for conventional solid wood floors. Its capability to copy the appearance of natural substances while delivering better toughness and straightforward upkeep is altering areas globally. But what precisely is this kind of flooring, and how do makers create it? This detailed guide examines the makeup, production method, advantages, and uses of this material. We will give you all the necessary details to decide wisely for your dwelling or business location.

Understanding Laminate Flooring

Often called “composite wood flooring” or “diamond board,” laminate flooring is a multi-ply artificial covering product built to imitate the look of natural substances such as timber or rock. Its standard designation, “impregnated paper laminated wood flooring,” shows its building method. This building involves stacking substances to make a strong, attractive covering surface. Unlike solid hardwood, this covering is engineered to provide increased toughness, cost efficiency, and adaptability. Consequently, it works perfectly for numerous surroundings, ranging from snug dwellings to busy commercial locations.

Why Choose Laminate Flooring?

This covering excels because it merges visual charm with useful features. Several vital factors explain its widespread appeal:

Cost Efficiency: It delivers the appearance of high-end materials like hardwood or stone at a much lower price.

Toughness: Its hard-wearing covering shields against scrapes, scuffs, and color loss. This makes it appropriate for places with heavy use.

Simple Care: The sealed covering resists stains. Cleaning requires only sweeping and a moist cloth.

Adaptable Appearance: Offered in many designs, hues, and finishes, it can resemble oak, walnut, marble, and more.

Sustainable Choices: Numerous producers, including Lanhe Flooring, emphasize eco-friendly substances and production methods.

Whether renewing a lounge, improving an office, or creating an open cooking space, laminate flooring provides a functional and elegant answer.

The Composition of Laminate Flooring

Builders construct laminate flooring from several plies. Each ply serves a distinct job to guarantee toughness, steadiness, and visual charm. Normally, it has four essential plies:

Layer Description Purpose

Wear-Resistant Ply A clear ply crafted from aluminum oxide or melamine resin Gives scrape, blemish, and wear protection. Shields the covering from everyday damage.

Decorative Ply A top-quality printed paper ply soaked with melamine resin Copies the look of wood, rock, or other substances using intricate designs and shades.

Core Ply High-density fiberboard (HDF) or medium-density fiberboard (MDF) made from over 80% wood fibers Supplies building power, steadiness, and knock resistance.

Balancing Ply A moisture-repelling ply, frequently crafted from resin-soaked kraft paper Stops bending and improves shape steadiness by opposing dampness and pressure.

The Role of Each Ply

Wear-Resistant Ply: This uppermost ply serves as a barrier. It protects the covering from scrapes, stains, and sunlight fading. Top-grade laminate flooring utilizes aluminum oxide for exceptional hardness and longevity.

Decorative Ply: The decorative ply is where the visual effect happens. Modern printing methods produce lifelike wood patterns, rock surfaces, or unique designs. This grants laminate its visual flexibility.

Core Ply: The dense core board offers the structural foundation. It guarantees the covering endures hefty furnishings and busy use without denting.

Balancing Ply: This bottom ply keeps the covering’s steadiness. It prevents moisture-related bending and ensures the pieces stay level and secure.

These plies function together. They form a covering answer that is both practical and visually impressive. This makes it appropriate for different installations.

How Is Laminate Flooring Made?

The production method for laminate flooring is an exact, multi-phase operation. It merges modern methods with excellent substances. Below, we detail the principal phases of making, using knowledge from market pioneers like Lanhe Flooring:

Raw Material Selection

The procedure starts with finding top-quality raw components. The core ply, normally made from high-density fiberboard (HDF), comes from timber fibers mixed with resin glues. Workers choose these substances cautiously to guarantee ecological security and building soundness. Additives such as calcium carbonate might be added to boost steadiness.

Core Board Production

Staff blend the timber fibers and resins. They press them under high heat and force to shape a solid, steady core board. This high-density fiberboard (HDF) supplies the basis for the covering’s toughness and knock resistance. Makers treat the board to improve its moisture-repelling and flame-slowing traits.

Decorative Ply Printing

Workers create the decorative ply using top-quality printing methods. This makes lifelike designs, like oak, walnut, or rock surfaces. They soak the printed paper with melamine resin. This boosts its toughness and water protection, keeping the design vivid long-term.

Ply Lamination

Staff laminate the four plies—wear-resistant, decorative, core, and balancing—together. They use a high-force, high-heat press. This method joins the plies firmly, making a unified, long-lasting piece. The lamination ensures the covering withstands regular wear while keeping its visual charm.

Surface Treatment

Staff apply a shielding coat, frequently containing aluminum oxide, to the top ply. This improves scrape and stain resistance. Some producers, like Lanhe Flooring, add UV coatings. These boost color permanence and guard against fading from sunlight.

Cutting and Notching

Staff cut the laminated boards into pieces of exact sizes. They notch them with a locking arrangement, such as Unilin or Valinge, for straightforward fitting. Precise cutting guarantees tight-fitting connections. This lessens height differences and forms a smooth, even surface.

Additional Treatments

Some laminate flooring items get extra treatments. These include sound underlays to lessen walking noise or micro-bevel edges to copy the look of solid wood. These improvements boost both usefulness and appearance.

Quality Control and Packaging

Before packaging, each piece goes through strict quality tests. This confirms it satisfies market standards for toughness, covering excellence, and ecological security. Staff then pack the pieces in top-quality printed cartons. They fasten them on pallets to avoid harm during moving.

This careful procedure guarantees laminate flooring is not only visually pleasing but also constructed to endure in demanding situations.

Benefits of Laminate Flooring

Laminate flooring offers numerous pluses making it a favored selection for many:

Economical: It supplies the look of high-end materials at a reduced cost point. Therefore, it is a budget-friendly substitute for hardwood or stone.

Long-lasting: The hard-wearing ply and thick core guarantee resistance to scrapes, dents, and fading. This makes it perfect for dwellings with animals or busy spots.

Moisture Resistance: Advanced laminate goods, like those in Lanhe’s Easy Line and Woodstock AquaBlock ranges, provide water-repelling features. This makes them fitting for cooking spaces and washrooms.

Simple Fitting: User-friendly locking arrangements permit speedy, glue-free installation. This conserves time and labor expenses.

Minimal Upkeep: The sealed covering stops grime gathering. Care requires only sweeping and a moist cloth.

Drawbacks of Laminate Flooring

While laminate flooring is highly adaptable, it has some restrictions:

Unrefinishable: Unlike hardwood, it cannot be sanded or refinished if the top ply gets damaged.

Moisture Harm Chance: Despite water-repelling choices, extended contact with dampness can harm the core ply.

Visual Realness: Lesser-quality laminates might miss the genuine look of natural substances.

Soundproofing: It can create noise when walked on. However, sound underlays can reduce this.

Lanhe Flooring: Your Trusted Laminate Flooring Supplier

When picking laminate flooring, teaming up with a dependable maker is vital for ensuring excellence and operation. Lanhe Flooring, a premier SPC and laminate flooring maker, merges modern methods with a pledge to sustainability and customer happiness. With years of background, Lanhe provides a broad assortment of customizable laminate flooring answers, from classic oak to contemporary rock surfaces. Their goods satisfy worldwide standards like ISO9001 and FloorScore. This guarantees longevity, security, and eco-friendliness. Whether improving a dwelling or planning a business area, Lanhe’s expert squad provides customized answers and outstanding assistance to realize your idea.

Conclusion

Laminate flooring is a flexible, tough, and economical answer for contemporary dwellings and business locations. Its multi-ply building merges a hard-wearing surface, lifelike decorative ply, steady core, and balancing ply. This guarantees enduring operation and visual charm. The careful making method, from raw substance choice to exact cutting, promises a high-quality result. It satisfies varied requirements. While laminate has some limits, its pluses—cost efficiency, simple care, and moisture resistance—make it a top selection for many. By selecting a dependable provider like Lanhe Flooring, you can improve your area with chic, trustworthy laminate flooring. It endures over time.

Frequently Asked Questions

What is laminate flooring made of?

Laminate flooring contains four plies: a hard-wearing ply for longevity, a decorative ply for visual charm, a thick core ply for building power, and a balancing ply for dampness resistance and steadiness. Staff laminate these plies together to form a sturdy, elegant covering answer.

How durable is laminate flooring?

Laminate flooring is very tough. Its hard-wearing ply guards against scrapes, stains, and fading. Its thick core board survives hefty furnishings and busy use. This makes it perfect for active spots like family rooms or business locations.

Can laminate flooring be used in kitchens?

Yes, many laminate flooring goods, such as those from Lanhe’s Easy Line and Woodstock AquaBlock ranges, are moisture-repelling. They are fitting for cooking spaces. However, extended contact with pooled water should be avoided. This prevents harm to the core ply.

Is laminate flooring easy to install?

Laminate flooring has user-friendly locking arrangements, like Unilin or Valinge. These permit glue-free, floating fitting. This makes it fast and straightforward to install, even for DIY individuals. It conserves time and labor expenses.

How do I maintain laminate flooring?

Caring for laminate flooring is uncomplicated. Regular sweeping and cleaning with a moist cloth and gentle cleaner keep the surface neat. The sealed, stain-repelling ply stops grime gathering. This ensures a low-maintenance covering answer.