Personalized customization, "control" as you like - Lanhe floor

Tired of the same old floor paving?

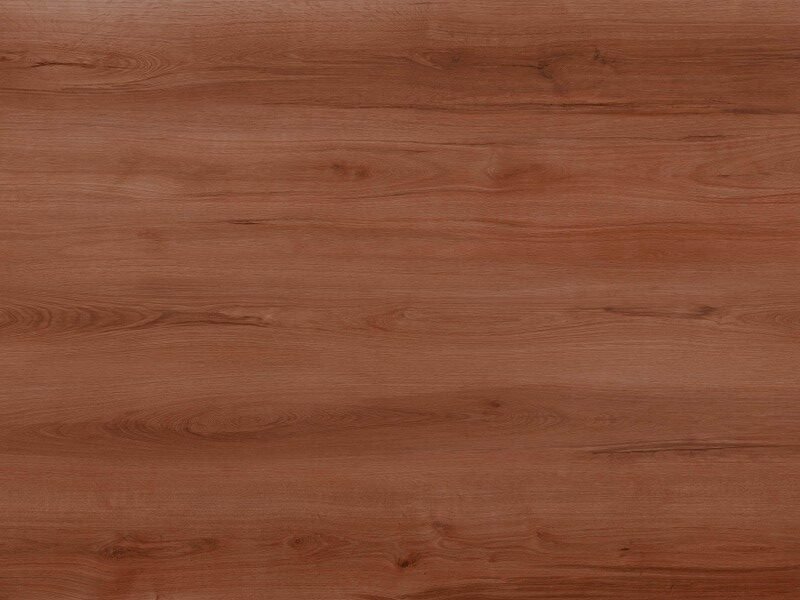

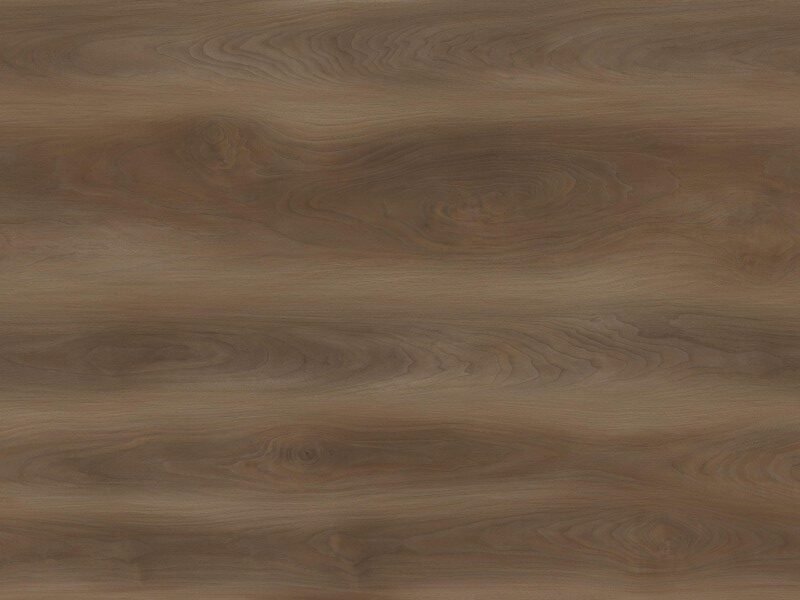

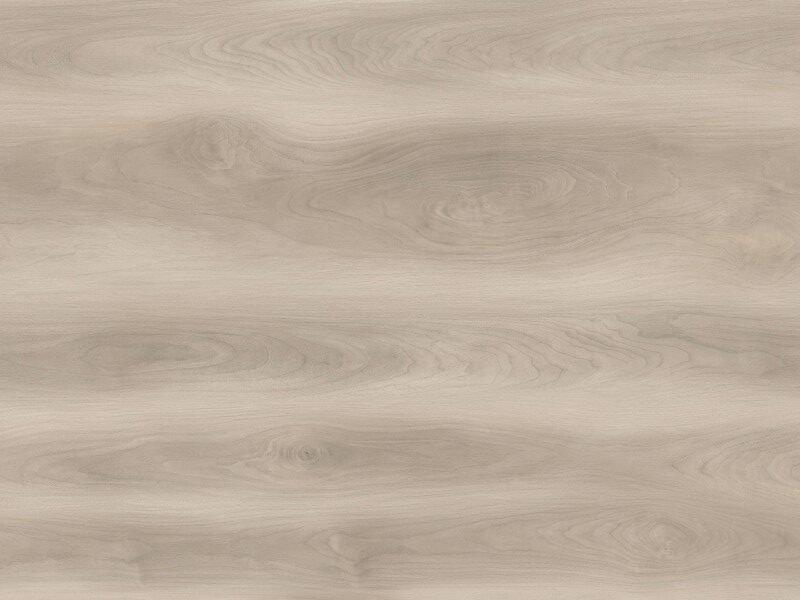

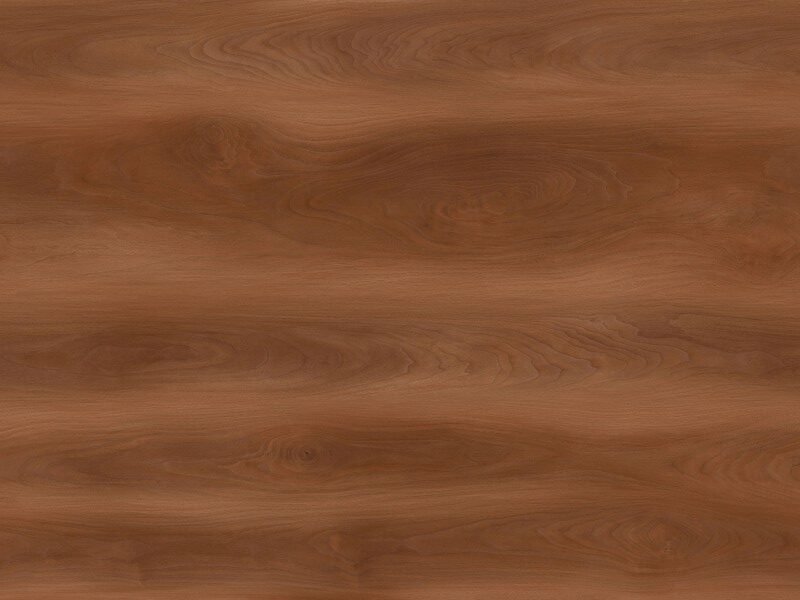

Lanhe floor customization service opens a unique space journey for you. Whether it is the creative conception of commercial space or the individual expression of home environment, we can tailor-make exclusive flooring. Rich colors, you can mix them; various patterns, you can choose; special textures, you can customize them. Every inch of floor can be integrated with your creativity and style, wear-resistant and stain-resistant, excellent quality, easy to install, worry-free and labor-saving. Lanhe floor customization, with professional craftsmanship, carves out your exclusive space aesthetics, so that every step you take, you step on a unique landscape.